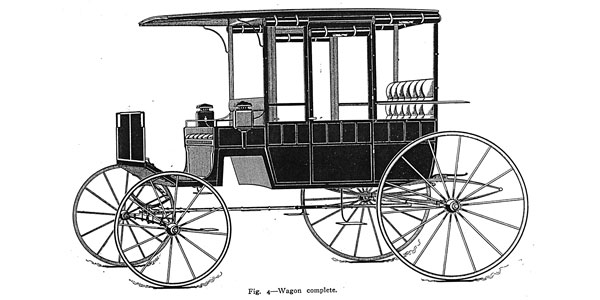

Six-Passenger Depot Wagon

reprinted from the June 1904 issue of Blacksmith and Wheelwright magazine

There exists a need in every part of the country where there is passenger transportation by rail or water a necessity for a vehicle for the comfortable conveyance of travelers, transient or commuters, of sufficient size to accommodate four grown persons at least, in addition to the riders on the driver’s seat. The large wagonettes serve the purpose fairly well, but all excepting those who occupy the driver’s seat must sit on seats that parallel the length of the body. To many this is decidedly objectionable from the standpoint of comfort, as well as from the restriction of vision to passing objects instead of the much longer view that is obtained by facing the direction in which the vehicle is moving, or by the continued view when looking rearward. Conditions such as these go far toward deciding the popularity of country and the hotel or summer home from which the vehicle is obtained. This fact accounts for much of the popularity of the twelve to fourteen passenger mountain wagons used in the mountain resorts, but the most enthusiastic advocate of this large spring wagon is slow to praise it for its comfort and to recognize its weakness as an ideal vehicle through its lack of protection to the riders from rain or sunshine. The standing canopy tops have partially corrected these faults, but there is still lacking that security and protection which can be obtained by the use of a fixed standing top, the high door, and the curtains in quarters and back as well as in the doorways. These can be had only by the use of the curtain quarter rockaway system, a system that gives thorough protection, provides for ample opening when the weather is clear and a whole or partial closing when conditions make it desirable. A fixed top is but little heavier than a canopy of proper portions, and is always ready for adjustment to suit the necessities of the case. It is because of these that the large depot wagon is popular, as in addition to its large seating capacity it possesses space for much small baggage. The space under the rear seat is made accessible by an end board which is hinged to the rear bar of the body by strong hinges and closes in just above the bottom line of the seat board. If provided with a chain support it can be let down and used to carry baggage that is too bulky to be placed under the seat. When this is not wanted it can be closed to shut from view the smaller parcels. In fact, it is this tailboard feature that constitutes the technical difference between a depot wagon and a rockaway, a distinction that is too often overlooked by builders when naming the vehicle. Let it become understood that a depot or station wagon, as it is sometimes called, is a vehicle with a body so constructed that access can be had to the interior at the rear by means of a door or lid that is hinged to fall down, and when closed in place it presents a finished rear panel, and there will soon be no misunderstanding when the point is raised as to its being a rockaway or a depot wagon.

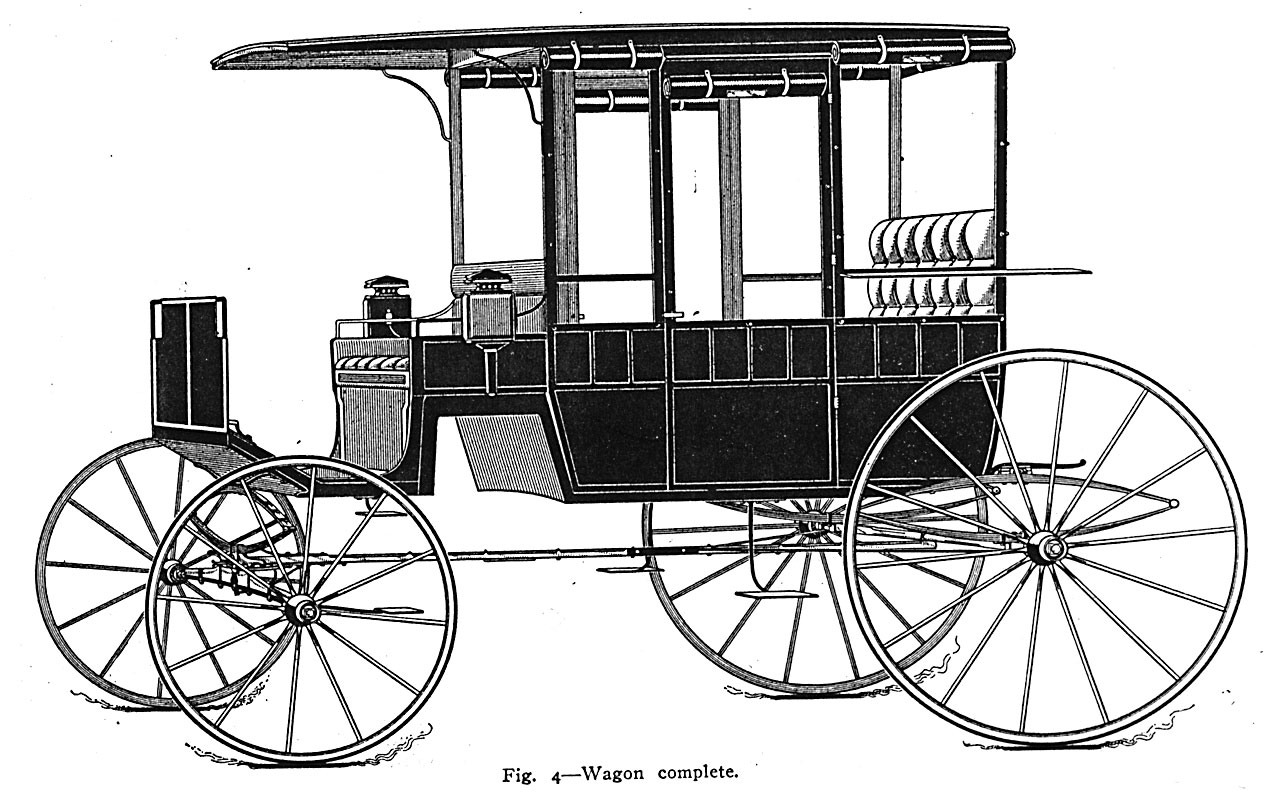

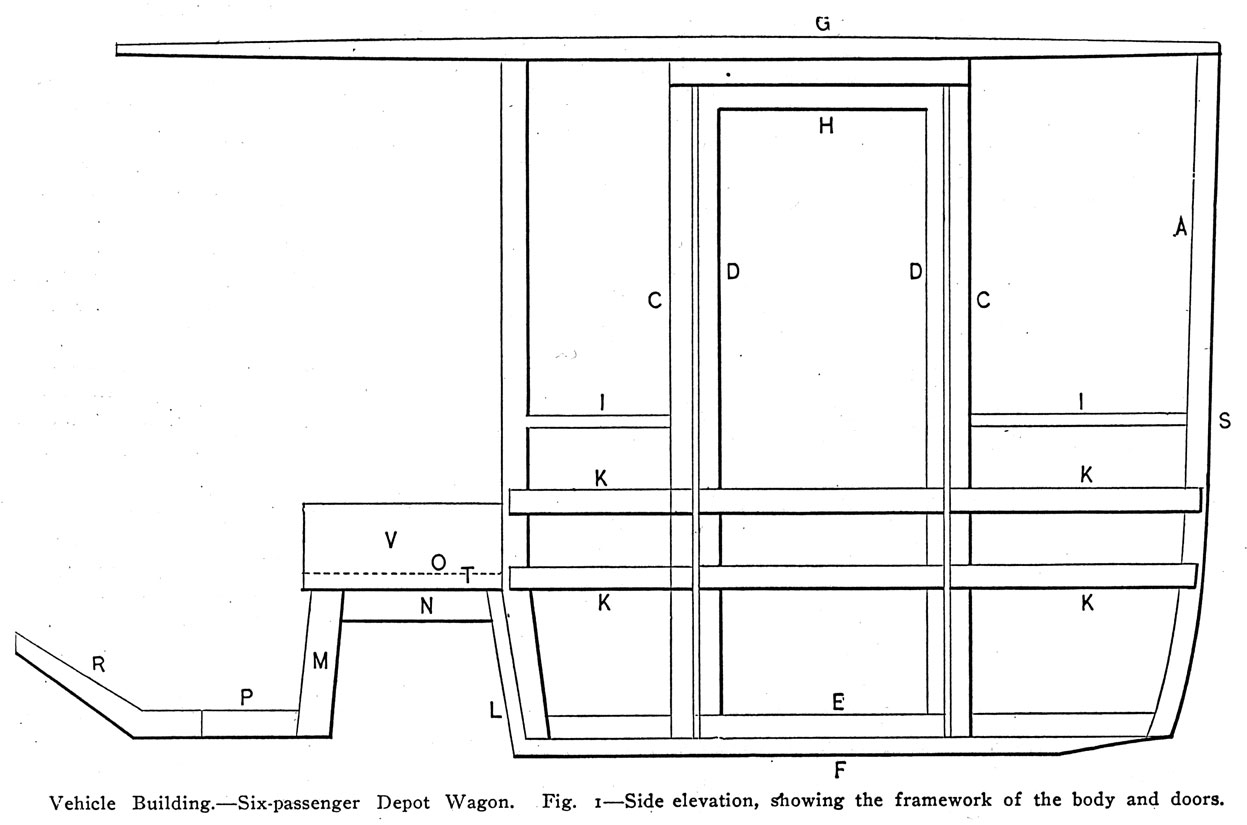

The vehicle shown this month is essentially a six-passenger depot wagon. The body is long, is hung low, and both in its cross width and the width of the seats it is roomy. The cutunder serves to lighten the appearance and provides ample room for the wheel to turn under so as not to rub against the reach and thus shorten its turning radius. In the construction everything tends toward simplicity. There are no sharply curved lines. The slight turnunder of the corner pillars at the back, as well as the slight turnunder of the sides, is not sufficient to necessitate the use of a side sweep to the top rail, but the forward ends of the top rail may be drawn together so as to narrow the front two inches at the front end rail, but this should be done without making a sharp bend at the front of the front corner pillar. This narrowing will not interfere with the protection from the top, but it will give a lightened appearance from the front view. The doors are cut through so that the bottoms come flush with the sill line of the body. The sills are not entirely cut away at the entrance, as the bottom bar of the door need not be more than 1 1/8 inches thick. If drop lights were used the bottom bar would have to be much heavier than it is with a door with lights. In getting out the timber all but the corner pillars can be of straight stock. The little turnunder on the sides won’t require door pillars that are more than 1 3/8 inches across at the rails; from that point up the pillars can be cut to one inch at the top.

Fig. 1 shows the elevation plan. A, the back corner pillar, cut straight down to S. B, the front corner pillar; this is in two pieces, which are spliced at T, or, if preferred, the pillar may be sawed in one piece, but both sections cut straight. C, the standing pillars. All the pillars should be 1 1/8 inches thick – that is, on the side faces above the arm rails – and 1 ½ inches deep at the rails and cut away from the inside to one inch at the top rail. D, the door pillars; these need not be rabbeted, but left plain on both faces. The moldings that cover the joints will keep out wind and water, while the guards at the top under the top rail and at the bottom on the sill will keep the door from rattling, providing the lock bolt binds as it should. It is a good plan to use india-rubber buffers, as they can be changed if the doors rattle after being in use. E, the bottom side or sill; this should be 1 3/4 inches deep and 2 ½ inches thick. F, the rocker; this is the main stay of the body and should be 3 1/4 inches deep and 1 1/4 inches thick. G, the top rail, one inch thick and 2 ½ inches deep at the center, the rear end lightened to 1 1/4 inches and the front end down to 1 1/8 inches. I, the upper arms rails, need not be more than one inch square. K, the lower rail or belt, should be 1 ½ inches deep and 1 1/8 inches thick; it must be framed to be flush with the outside of the pillars and boxed out for the panels D. The center belt rail, one inch thick and two inches deep. The splice pieces around the wheelhouse, L, M and N, are of the same thickness as the rocker F, and not less than two inches wide at any point, as they must be of sufficient proportions to provide good rests for the rocker plates. The headpiece P and the bracket R must also be the same thickness as the rocker pieces and cut to pattern on the upper lines. The rear corner pillars are cut to a sweep below S and a slight turnunder on the sides. All the framework of the quarters and doors, with the exception of the top rail, which has an overhang of one-eighth inch, must be worked up flush below the top line of the rails K, the cutaway below this line is three-eighths of an inch, which allows for the panels. All moldings are to be nailed on. The front seat end is of one-inch whitewood, secured to the rockers, which extend up to the dotted line O.

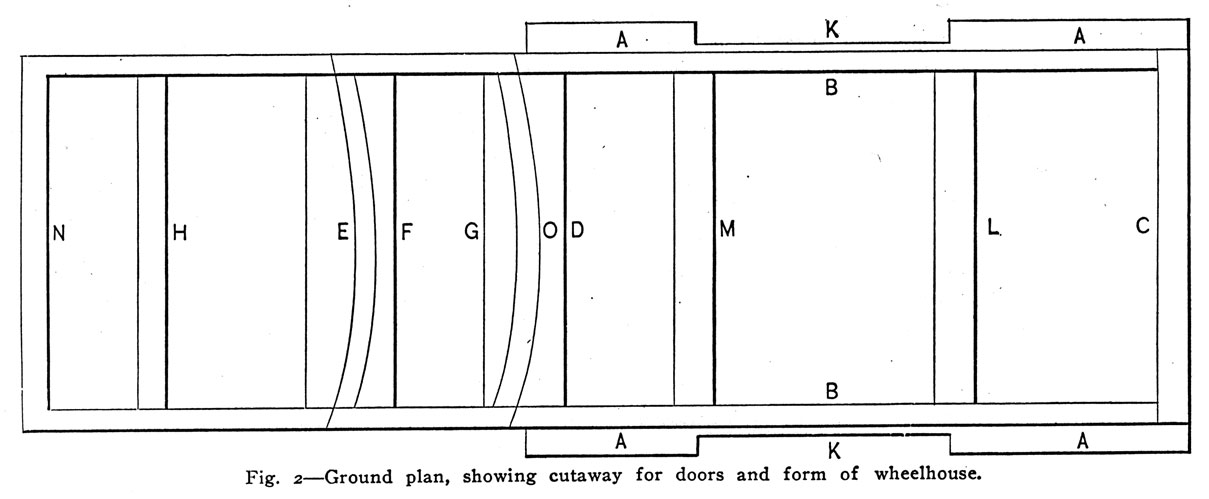

Fig. 2 shows the ground plan. The bottom side A extends from the front to the rear corner pillars; the section K is cut away to allow for the lower door bar, which finishes on a line with the bottom of the sill. The sill is secured to the rocker by long screws. B, the rocker, which is framed up to the same width front and rear, the projecting of the sills being sufficient to give the proper difference between the outside and inside seats. The rocker should be 1 ½ inches thick, and when the pieces are framed around the wheelhouse the laps should be well glued and screwed. The rocker plates should extend the whole length of the rocker and be provided with lugs on each end to bear against the end bars, to which they must be secured by heavy screws. The rear end bar C is mortised into the sills; the front end bar is lapped on the rocker. The face should be cut at right angle with the top to provide a level bearing for the rocker plate lug. D, the lower rear wheelhouse bar, should be one inch thick and cut to the swept line O; the upper rear wheelhouse bar G has the same sweep as the line O. The rear wheelhouse panel is nailed to the forward edge of the bar D and to the rear of the bar G. The bar E is the heel bar of the front, as well as the lower bar for the wheelhouse. F, the upper bar for the front of the wheelhouse, corresponds with the bar G. If preferred, the whole space between the rear of the bar G and the front of the bar F may be of one one-inch board; this saves work and makes just as good a job as the two bars and the panel over them. M, L and H show the locations of the remaining cross bars.

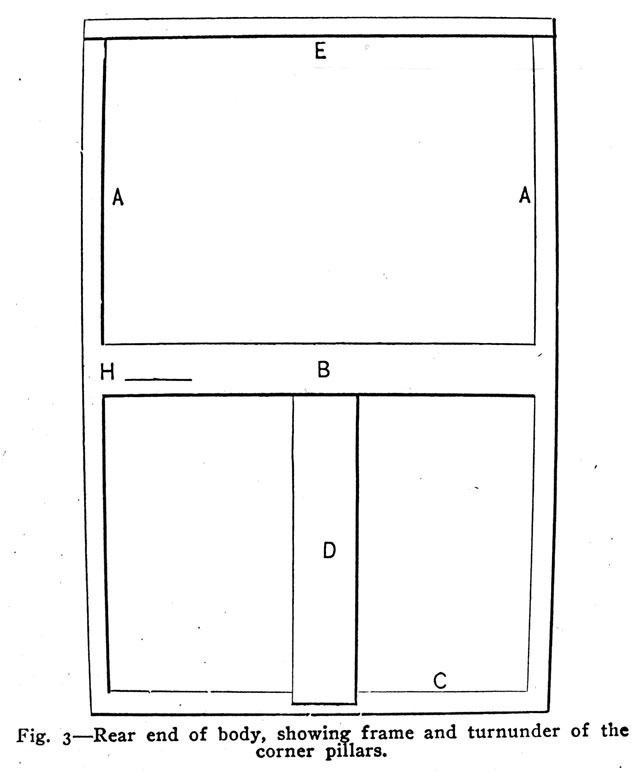

The rear end of the framework is shown by Fig. 3. A, the corner pillars; B, the back rail; C, the back bar; E, the top end rail, and D, the panel strainer. The panels are set in their full thickness up to the dotted line H, which represents the top of the rabbet. It is well to rabbet the pillars down to the top of the belt line K, Fig. I, from which point down the panels are mitered. All the work is plain and simple and should be within the range of the ability of any man who professes to be a bodymaker.