Grain Drills

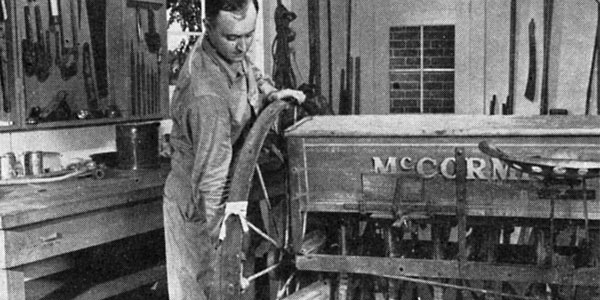

Care and Maintenance of Grain Drills

To begin the calibration of the grain drill, first, partially close each seed gate; then pour some grain into the seed box. Place a canvas under the drill to catch the grain. Be sure that the canvas is under all seed tubes. Lay a board under the drill to protect the canvas when the furrow openers are lowered to operating position.

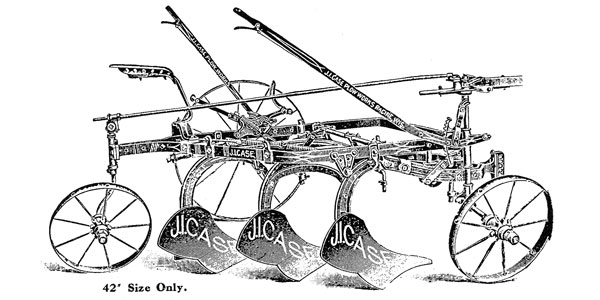

Case Horsedrawn Farm Implements

The illustrations on these pages come from an old J.I. Case catalog loaned to us by Judson Schrick of Decorah, Iowa. We reprint them here for you because, as in the past, there have been those of us who have been able to make good use of this information when we go to repair or restore one of these plows or whatever. For many of us, there is no other place to go for this kind of information but right here in the good old SFJ. Some of you already have this stuff in your shop library. Some of you don’t like this stuff and will never need it. Hope both of you will tolerate the rest of us as we go on preserving some great relic technologies. Remember, tractors may come and tractors may go but good horses are born, every day

How To Set Your Grain Drill

Since the rate of seeding any oats with a grain drill will vary considerably with the degree of cleanness of the oats, the most satisfactory method of determining an accurate drill setting for any particular lot of seed is by a calibration test. To make this test, raise and block up one side of the drill so that the wheel on that side will turn freely. The seed dropped by a certain number of revolutions of the wheel should be collected in cans, paper sacks, or on a canvas spread beneath all drill tubes. The table shows the number of wheel revolutions for various drill widths and wheel diameters to cover 1/10 acre.

John Deere No. 919 Corn Drill

The right-hand wheel is the driver, and is held in place by means of a large spring cotter, while the left-hand wheel is held by the two collars, one on each side of the wheel. See that the wheels are in line with the runners. For a team of average size, tongue casting should be in the center adjustment, raising or lowering according to the size of the team so that the front runs level.

John Deere-Van Brunt Combination Fertilizer Grain Drills

Practically all trouble with new machines is due to improper setting up, faulty adjustments and lack of oil. The object of these directions is to assist you in setting up this machine correctly and operating it to the best advantage. By carefully following these simple instructions, one person can set up the machine. 1. Place all bundles where they will be handy.

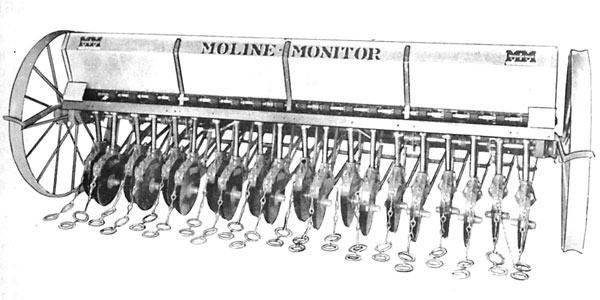

Minneapolis-Moline Monitor Drills

Tests on wheat and coarser grains have shown that a high speed gear, resulting in a faster revolving feed shaft, and with the fluted feed cylinder partially closed, will produce a more even and continuous flow of seed than a low speed gear setting with the cylinder opened sufficiently far to sow the same amount of seed. This is true unless the seeds are so dry or so large that a narrow opening of the fluted cylinder would cause them to crack.

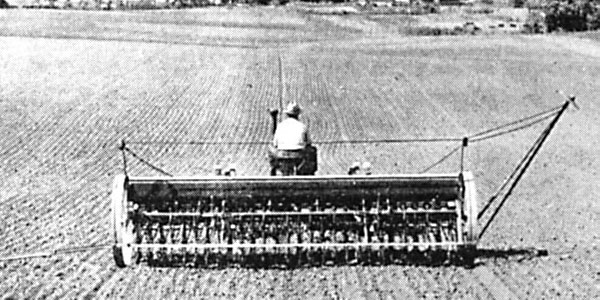

Seeding Machinery For Small Grains

The most satisfactory method of sowing any of the small grains is with the grain drill. The largest yields are obtained from fields where the seed have been deposited evenly and in the right amount in a firm, compact soil and covered at a uniform depth. It is practically impossible to secure these conditions when the seed are sown with a broadcast seeder.

The Harvest of Grain

When you watch a field of wheat turn from green to golden and wave lightly in the wind, see the shocks lined up in rows as you pass by on the road, watch a load of grain auger into the grain wagon, and then see the cycle begin again. It is beautiful and worth it all.

Van Brunt Plain High-Wheel Drills

Grain must not be left in box after seeding. To clean box, drop gates. Disks and other important parts of machine would be covered with oil or grease, and the machine put under shelter. Good treatment prolongs the life of your machine.