Eighteen Dollar Harrow

Eighteen Dollar Harrow

by Justin Reynolds of Glouster, Ohio

Eighteen Dollar Harrow Plans (PDF)

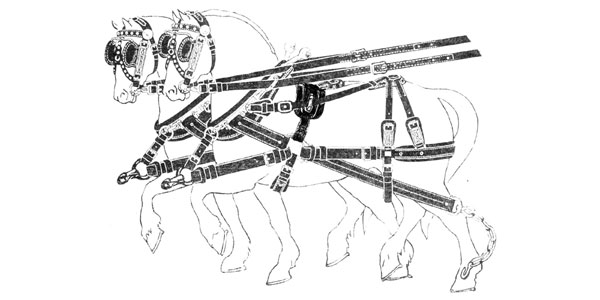

This is the story of a harrow on a budget. I saw plans on the Tillers International website for building an adjustable spike tooth harrow. I modified the plans somewhat to suit the materials I had available and built a functional farm tool for eighteen dollars. The manufactured equivalent, a metal three foot spike tooth harrow, would have cost at least $300.

The original Tillers design calls for a combination of wood and metal materials. I used wood for some of the pieces they had called for to be metal because that’s what I had available. The wood I used is oak I had on hand from a dismantled barn and the spikes are eight inch pole barn spikes which I purchased new. I originally scrapped together the nuts, bolts and washers which connect the moving parts but I ended up just buying some so it would be uniform and more functional. The bottom of the runners have a strip of metal for added durability.

I began the project by working on the runners. I used two pieces 1-3/4” x 4-1/2” x 63” and a half inch paddle bit to drill holes 10” apart, centered on the 4-1/2” side, starting 13” from the front. I rounded off the front of the runners with a chainsaw.

Next I created what we’ll call the cross members. They are made from five pieces 1-3/4” x 2-1/4” x 46”. Then, 2” from each end I used a table saw with the blade set about 1/2” high to make a cut on all sides. After that I used a mallet and chisel to make the ends rounded to fit into the holes in the runners. Finally, I drilled holes 10” apart into the 1-3/4” side starting 6” from one end to put the spikes into. I was careful to drill the holes slightly smaller than the spikes, so they would stay in place but not so small that the wood would crack as I pounded them in.

My next step was to fit the cross members with spikes into the runners. Cross members next to each other are reversed so the spikes are offset. Then, I screwed one 1-1/2” x 3-1/2” x 46” piece at the front and back of the runners on the top, to hold them together.

Then, I began to assemble the moving adjustable parts. There are five pieces of 1-1/2” x 1-1/2” that I screwed in the center at a right angle on the 2-1/4” side of each cross member. The front four are 16-1/2” long and the rear one is 42” long and serves as a handle. We’ll call these the vertical members. Once these were attached I drilled 3/8” holes 2-1/2” from the top of each vertical member going left to right as the harrow sits.

Next, I used a piece 1-1/2” x 2-1/2” x 43-1/2” that we’ll call the horizontal member and drilled 3/8” holes every 10” centered on the 2-1/2” side, starting about 2” from one end. Then, I attached the horizontal member to the right side (when viewing from the rear) of the vertical members using 4” bolts with lock nuts. I put washers on each end of the bolt and also in between the horizontal and vertical members. Now all the cross members rotated in unison by moving the rear vertical member. When in use this allows the angle that the spikes contact the ground to be adjusted to the desired level of aggressiveness. The spikes can also lay almost parallel to the ground when transporting the harrow to the field.

In order to keep the spiked cross members at the desired angle when in use I attached one final addition we’ll call the adjustable member. I took a piece 1” x 2” x 21-1/2” and drilled a 3/8” hole centered on the 2” side 3” from one end and drilled a 7/8” hole 2” from the other end. Then I drilled a 3/8” hole centered on the rear vertical member 16” from the top going left to right as the harrow sits. I attached the adjustable member to the rear vertical member through the 3/8” holes using a 5” bolt with a lock nut. I put an additional piece 1” x 2” x 2” with a 3/8” hole in the center in between the rear vertical member and the adjustable member as a spacer. On each end of the bolt and in between each piece of wood I put a washer. Then I drilled five 7/8” holes centered on the 2-1/2” side of the horizontal member about 2-1/2” apart starting 16-1/2” from the front of the horizontal member. Now, using a hitch pin, the remaining hole on the adjustable member can be connected with any of the holes on the horizontal member to hold the spiked cross members at the desired angle.

At this point I nailed a strip of old tin roof to the bottom of each runner, thinking this would decrease wear on the runners.

My final step was to drill 1/2” holes in the top corner of the front of each runner and attach a metal cable in between. It has a knotted loop in the middle and this is where I attach the single tree.

After all this I ran to the barn and yoked up my steer to try it out. He didn’t seem impressed but I was grateful and youthfully excited to be the owner of a brand new and fully functional eighteen dollar spike tooth harrow.

In the spring, we used the harrow to smooth some disced ground and in the fall to smooth some ground as well as work in wheat that was broadcast seeded. My only criticism is that it has a tendency to get clogged up with any surface debris, which then needs to be cleared. This isn’t difficult but does interrupt the flow of work. The manufactured version has a convenient spring mechanism for doing this, whereas the one I built takes two hands and a few more seconds. Otherwise, I’m happy with the performance and glad to have saved the few hundred dollars.

Materials list:

- Two 1-3/4” x 4-1/2” x 63”

- Five 1-3/4” x 2-1/4” x 46”

- Two 1-1/2” x 3-1/2” x 46”

- Four 1-1/2” x 1-1/2” x 16-1/2”

- One 1-1/2” x 1-1/2” x 42”

- One 1-1/2” x 2-1/2” x 43-1/2”

- One 1” x 2” x 21-1/2”

- Twenty 8” pole barn spikes

- Five 4” long 3/8” bolts with lock nuts

- One 5” long 3/8” bolt with lock nut

- Nineteen washers with 3/8” holes

- Some three inch screws

- One hitch pin and clip

- Some old tin roof and some 1-1/2” nails

- Length of cable or chain

Resources: www.tillersinternational.org