Apple Cider, Autumn’s Nectar

Apple Cider, Autumn’s Nectar

by Elizabeth Biggs of Quebec

I have often thought that I would not care to live where seasons do not change. My mind and body seem geared to our climate; the reawakening of spring, the blossoming of summer, the ripeness of autumn, the expectancy of winter. This past fall season has been a particularly beautiful one in our country-side of south eastern Quebec. We were blessed with day after day of warm sunshine. The memory of those warm summer like days and the vision of the brilliance of the autumn colours will shelter and comfort us in the long winter days ahead.

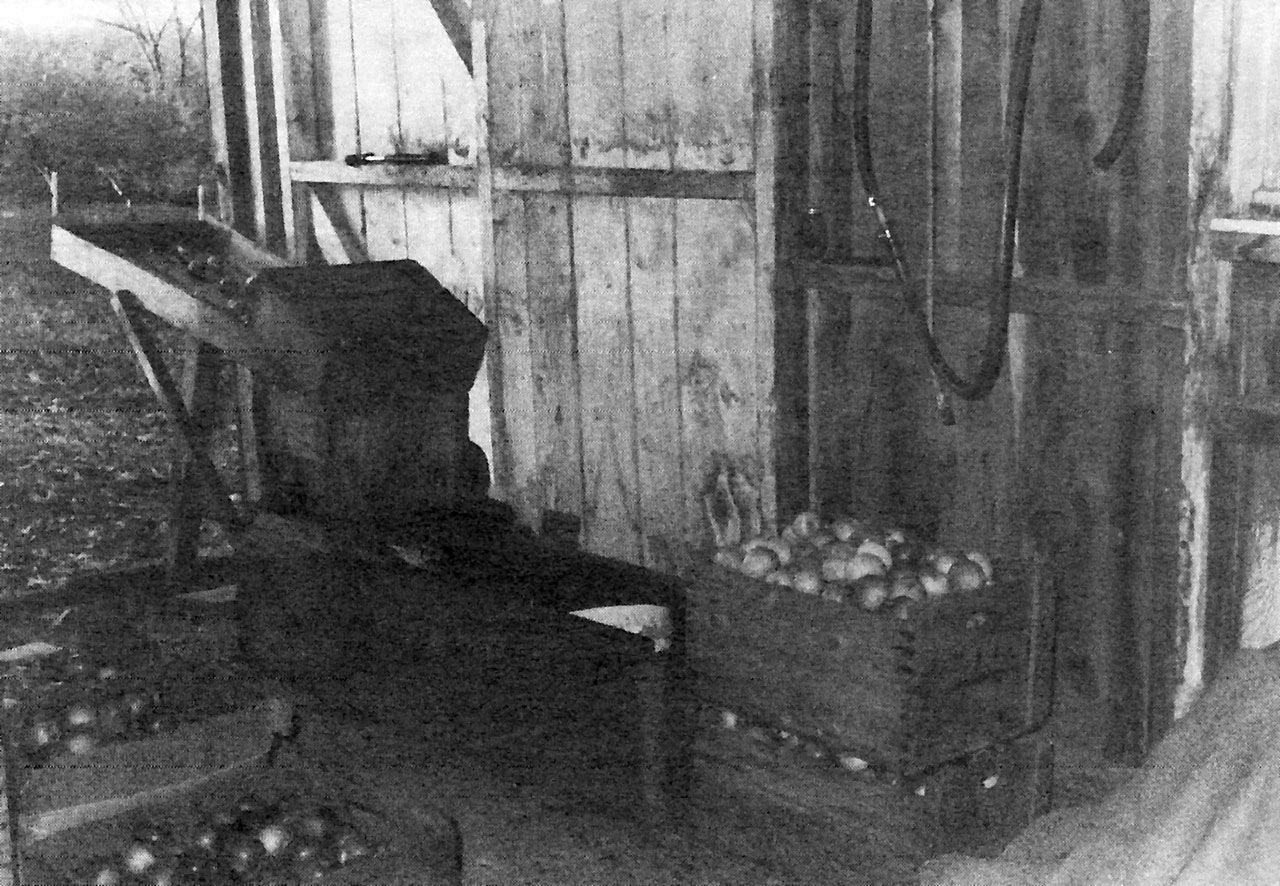

While autumn’s beauty is food for our souls, autumn’s harvest provides food for our tables. Along with the many hours and days of canning and freezing our garden produce, harvest time also means apple cider making for our family. We have been making apple cider or sweet cider as it is commonly called for six years. At an off season for cattle hoof trimming which provides the main source of income for our livelihood, cider making sees us through those lean months. That same possibility exists for anyone living in an area where apples are plentiful. Beginning slowly, the demand for our juice has resulted in a production of over six hundred gallons this year, providing a source of that scarce and illusive commodity for most small farmers, CASH!

We live in an important apple producing area of our province; in fact we are surrounded by large commercial orchards in our neighborhood. Our own small orchard of twenty trees of MacIntosh, Melba, Lobo, and Cortland apples cannot begin to furnish enough apples for our cider making. The rest we buy from these large commercial orchards. By buying ground apples and doing our own picking and transporting, the cost of two dollars per bushel is quickly multiplied in the finished product. Our yield usually averages three gallons of cider for one bushel of fully ripened ground apples.

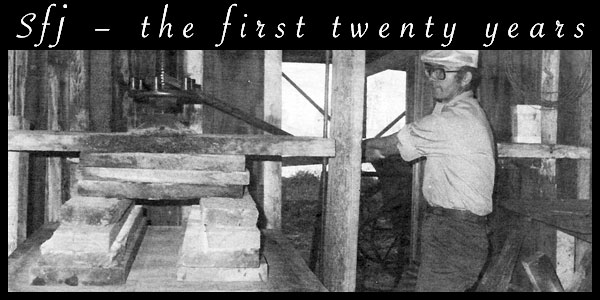

We bought our cider mill from an old-timer who had built it some twenty years ago and we still admire the simplicity and ingenuity of it’s design. Unfortunately, poor health ended Mr. Clough’s cider making days, but he seemed glad to know the mill would still be in use. Anyone with some basic carpentry skills could build his own mill as well. The mill consists of two parts; the grinder and the press. (see diagram). The grinder consists of a wooden cylinder studded with nail heads which is mounted on a long narrow box. Apples are fed gradually into the grinder powered by a half-horse power electric motor and the resulting apple pulp is collected in the wooden box.

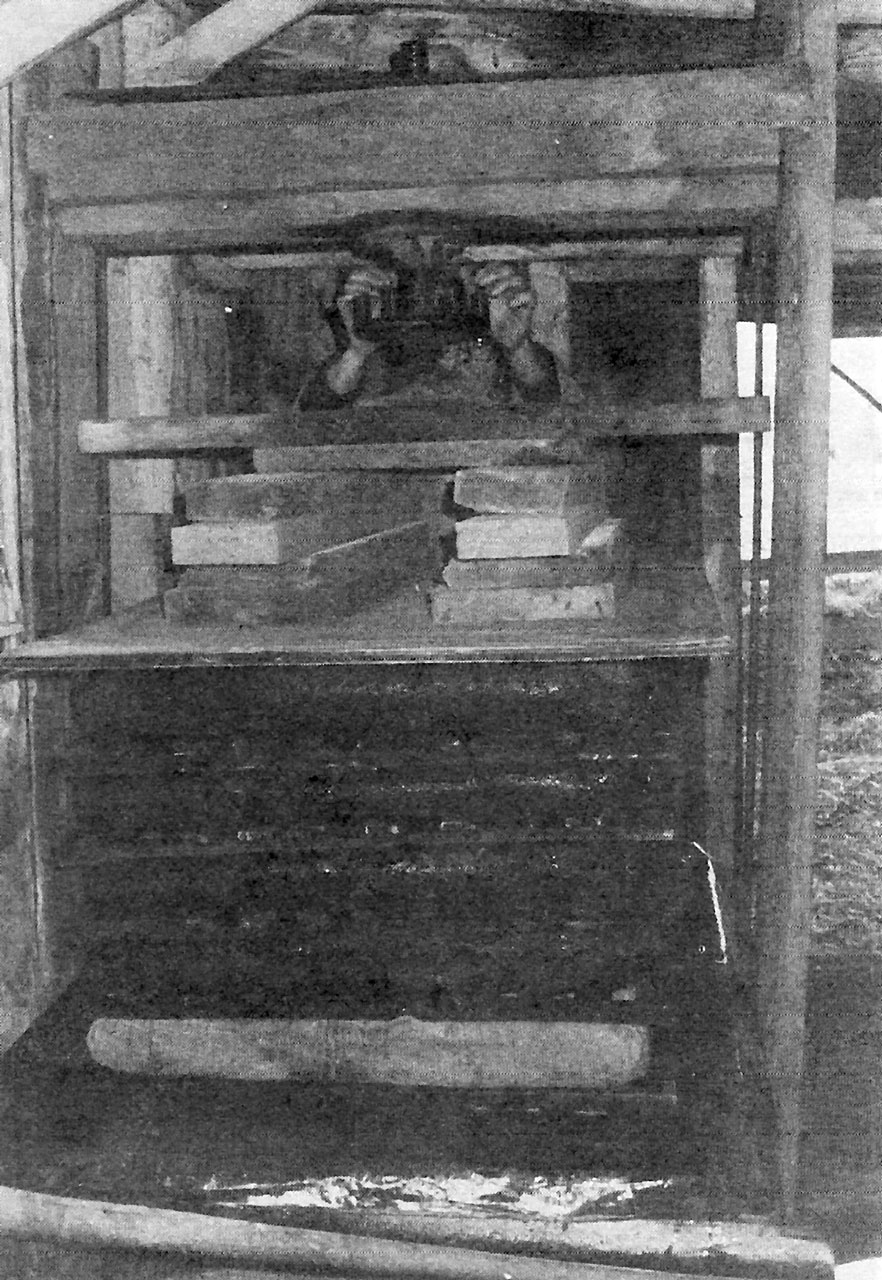

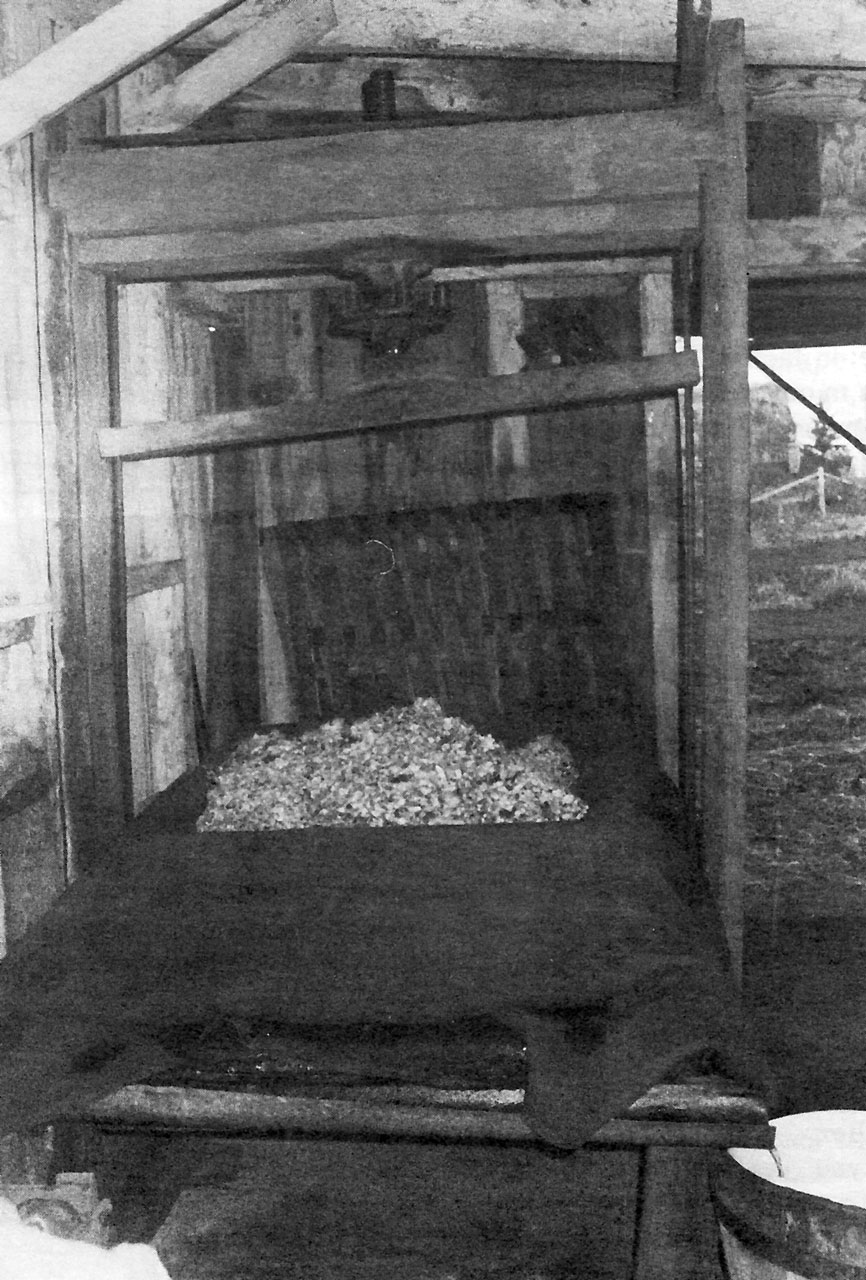

As you can see from the diagram the press is basically a sturdy wooden frame and a mounted screw. The idea is to build up layers of crushed apples in order to press out the juice. Wooden slatted racks are placed between the layers to provide space for the juice to run out of the press into a collecting barrel. A wooden shaping frame is placed on the first rack, a burlap liner is arranged over the frame, to which is added the crushed apples. As each layer is filled, the process begins again, rack, frame, liner, apples. Approximately twenty-five bushels of apples and five layers fill our press. Now the actual pressing can begin. A piece of plywood is placed over the last layer of apples, some wooden blocks are used to fill in the empty space between apples and pressing board, a metal bar is placed in the screw head, a couple of turns and voila! Sweet autumn nectar – fresh apple juice. This is apple juice like no other you’ve ever tasted.

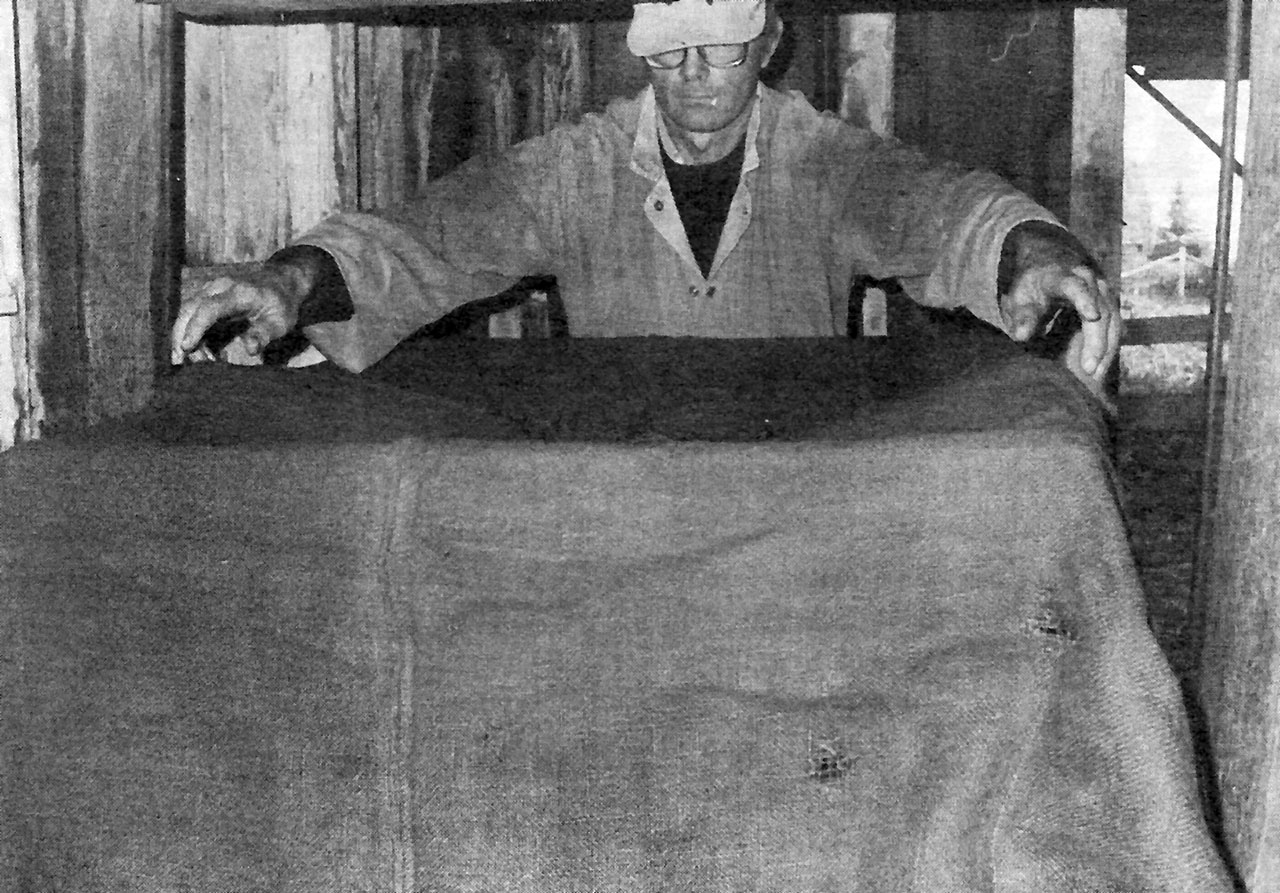

We filter our juice through one layer of clean white cotton (I use old flour bags) into milk cans. The cider is ready to be bottled.

Old timers say that only wood should come in contact with apples. The corrosive quality of apple juice will quickly pick up a metallic taste, so bottle up that juice quickly. We use old wine jugs salvaged from our wine drinking friends garbage that have been thoroughly washed and scalded. Sweet cider is a short life product. In warm temperatures and even in the back of the refrigerator it will quickly start to ferment. But then many of our customers say they like their juice a little picky. Just be sure to loosen the cap or you might lose an eye when you come to sample that rare vintage of week old cider. We try to bottle all our juice and peddle it the same day. We have built up a reliable clientele who are more than anxious to buy fresh apple juice delivered to their door.

Face view of cider press with first layer of apples being filled (note cider already running out of press).

Always remember, if you want to make good cider, be clean, right from the beginning with the apples (no I don’t agree a few slugs add body to the flavour) to the grinder and press which receives a thorough scrub down after each batch is made. I made our burlap liners from cattle feed bags taken apart in the seams and sewn together on my sewing machine, four bags for one liner. Be sure to boil the bags first, followed by several washes and rinses in the washing machine. Don’t make my mistake and omit the boiling. Our first batch of cider had a decided flavour of cattle feed. That batch of cider watered my tomatoes.

We put up about forty gallons of cider for the winter by bringing the juice just to the boil and putting it in scalded bottles. Be sure to boil the caps too. If there is room in the freezer, that’s the best place to keep cider. My freezer is usually so full of meat and vegetables there isn’t room. Pasturizing does alter the flavour a little, but it’s still good drinking.

I’ve added two recipes that I use every cider season. If you are ever up our way some crisp October day drop in. If there is nobody home, just head on up the hill to the cider mill. We’re probably there knee deep in apples and cider. Bring along a glass. I’ve got a bottle of the good stuff set aside for you.

HOT SPICED APPLE CIDER

- 1 gal. fresh apple cider

- 3 tablespoons honey

- 1/2 lemon thinly sliced

- 12 whole cloves

- 1 cinnamon stick or 1/2 tsp. ground cinnamon

To 1 gallon of juice add other ingredients. Bring to a boil. Simmer 10 minutes. Strain and enjoy!

APPLE BUTTER

- 13 sliced and cored unpeeled apples

- 2 cups fresh apple cider

- 2 cups sugar

- 1 tsp. ground cinnamon

- 1/2 tsp. cloves

- 1/2 tsp. nutmeg

- 1/2 tsp. allspice

Cook apples and cider together uncovered until apples are soft. Put this pulp through a sieve. Add sugar and spices to this pulp and cook over low heat until thickened stirring occasionally. (Approximately 20 min.) Ladle into hot sterilized jars and seal. Delicious on hot homemade bread.