Home & Shop Companion #0114

letter from a small corner of far away

Dear Lynn, dear Everyone,

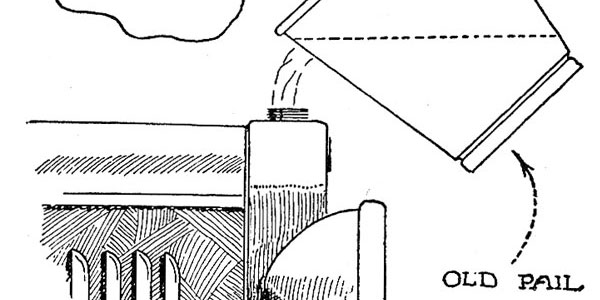

As expected, the cold wind from the north descended last week and I am hoping it won’t have wiped out the plums, as the blossom on the damsons, plums and ornamental cherries has just started to open. Before the cooler weather came I finished cultivating the vegetable patches in the field, harrowing twice over the ground for the onion sets and other vegetables grown from seed, while the potato patch had two passes with the spring tine cultivator, set a little deeper each time, followed by the roller. I am not sure how much good the rolling usually does, but I like the more solid surface before throwing the land into ridges, and the even surface allows a better mark to be made with the bout marker attachment on the ridging plough. This year, however, you could see how the roller crumbled the small clods on the surface too, a job sometimes thought to be the whole purpose of a roller, but I appreciate it just as much for consolidating the soil to allow the tined implements that follow to break the soil against itself.

This year I have been using a new spring tine cultivator, new to me at least. Last autumn the old one started to come apart so the last time I used it, I had to tie it together with some rope. There had been slop in all the joints ever since I bought it, but it was cheap, so although it did break up the soil, it was an approximate tool. And really it should be quite a precise implement, with all the tines working at the same depth. When set shallow, the tines are at right angles to the soil surface so the soil is pushed against itself as the tine moves forward. As it goes deeper the tine point faces ever forward, pulling what is a light implement into the ground, while there is still enough resistance above the tine for the soil to break up. But besides being loose in the joints, the tines were so unevenly worn that there was a couple of inches difference in depth between the tines. So depending on exactly where the cultivator was driven on a subsequent pass, some tines were not working any deeper than before, whereas others were running much deeper against some more solid soil where a shallow tine had been before.

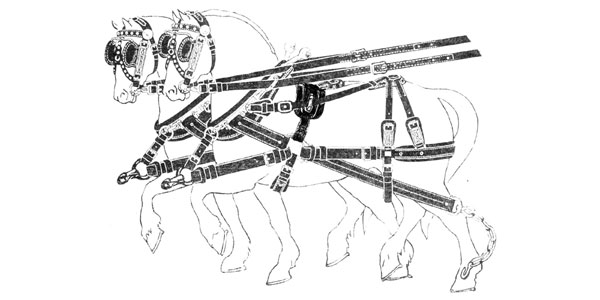

The new one, at least it was new perhaps seventy or eighty years ago, is much better, with the tines of similar length and still quite a lot of light blue paint on the frame. Over the years, however, the bolt holding the depth lever had rusted to only a quarter of its original thickness, and sheared when I tried to undo it despite heating it up first. Once replaced, all three rows of tines now rotate at the same speed, so work at the same depth. The downside of the new cultivator is that it was made to be part of a pair, which bolt loosely together, and the hook at the front is not central, which makes it pull at a slightly squiffy angle. Also, when I went over the ground for the second time, a little deeper, the rear row of tines did not sink in as far as the front, the whole thing was running on its toes. It had an easy remedy, just shorten the draught chain, in effect, lifting the front, but it also started wobbling from side to side which would not a problem had two sections been fastened together. Nonetheless it worked, but as I carried on, I started thinking how to stop the oscillation, which I could do by having two chains from the swingletree, one to each side of the cultivator. Thinking about it some more and looking at the old cultivator, which was definitely intended to be drawn by a horse, it has a C-shaped frame attached at both ends to the sides of the cultivator frame where the pivot for the first row of tines is. It then has a number of holes from which to attach a draught chain or two. So the pull is directed more towards the centre of resistance, whilst the double points of attachment should limit the side to side oscillations. Well, I expect so. So sometime this summer, I am going to weld on some eyes to the new cultivator frame and fit the shortened C-shaped pulling bar from the old cultivator and see if it helps. I’ll let you know how it goes.

Meanwhile, I am still in winter mode with the horses, leading Lucy in each night. When the weather was hot last week, it was tempting to turn her out already, but the grass has basically stood still since then, and of the livestock, work horses were traditionally the last to be turned out, often well into May. So each morning I give Lucy a small feed before I have my breakfast, then with a bucket full for Molly on my left arm, I lead Lucy to the field, tie her to the gate post and give the feed to Molly. Lucy is used to this, being tied up securely is something that has happened since she was small, and she doesn’t try to get loose because she learnt this when she was small, though she does sometimes paw at the ground and gets her foot over the lead rope. And she is used to this too. By the time I have checked the water and done the hay, Molly has eaten the best bits, the protein- and fat-rich micronized linseed meal along with a little oats, so sometimes Lucy gets to share in the soaked sugar beet after I turn her loose. When I am away, I have a reliable horsewoman who comes to do the horses, and for those few days the horses just get fed together. “Are they happy eating together,” she asked the first time, and they are, because both grew up having to share, at least some of the time, so that is what they do.

Take care,

William

William Castle is a violin maker, farmer & SFJ contributor who lives in Shropshire, England.